Hemp has been valued for its strength and versatility since prehistoric times. Shrouded in controversy over family ties, hemp production lost nearly a century’s worth of momentum and is only recently making a comeback as one of the most environmentally-friendly natural fibers.

Cannabis cousins

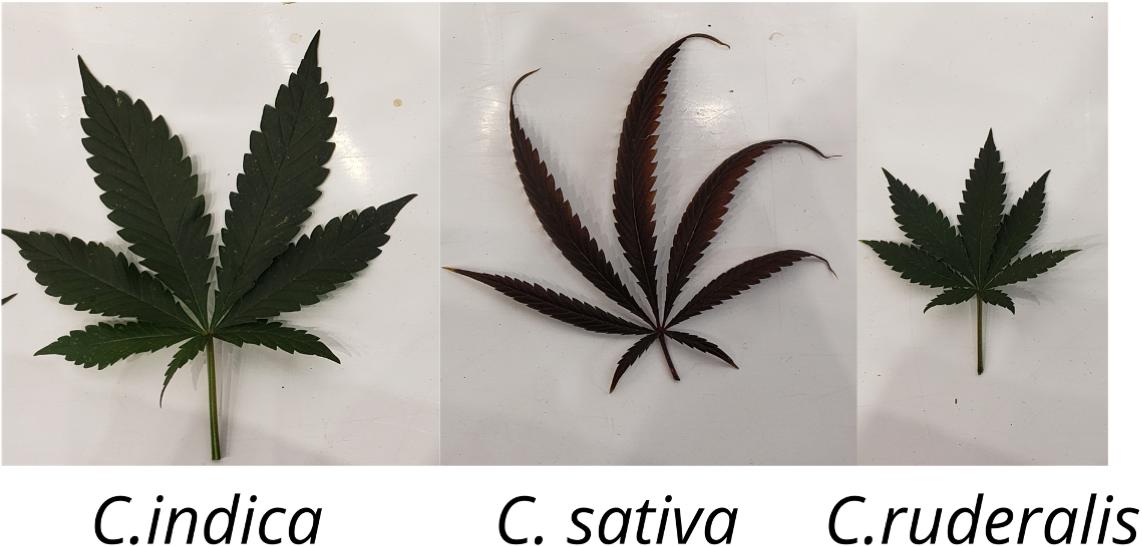

Many make the mistake of assuming cannabis is cannabis, without acknowledging any distinction between hemp and marijuana, two species within the genus Cannabis; yet the differences are nothing to sneeze at.

Hemp (Cannabis sativa), for instance, grows a good 10 feet taller than marijuana (Cannabis indica), making it an ideal fiber crop. In addition, hemp concentrations of tetrahydrocannabinol (THC) — a chemical with psychoactive properties — are negligible (limited to 0.3 percent), while marijuana could have anywhere between 10 and 27 percent THC.

A third species, C. ruderalis, is rarely cultivated because it lacks both height and THC content.

A brief history of hemp

Chinese and Japanese samples of pottery from the Holocene period (decorated with impressions made by hemp cord) indicate that the use of hemp as fiber dates back at least 10,000 years. Remnants of 8,000-year-old hemp fabric in the form of woven textile were also found in China. The first recorded cultivation of the plant occurred in China, around 2,800 BC.

Success

You are now signed up for our newsletter

Success

Check your email to complete sign up

By the first millennium, hemp production had spread to Europe. Easy to grow and resistant to decay, hemp was practically indispensable for Vikings and other seafarers. It was a choice fiber for sails, ropes, fish nets, and even caulking. Hemp arrived in South America shortly before being introduced to North America in the early 1,600s.

Starting in 1619, property-owning settlers in Jamestown, Virginia (and later in Massachusetts and Connecticut) were required by royal decree to grow hemp for export, providing canvas and cordage for British ships. Early Americans also used the fiber for clothing textiles, grain sacks, canvas for covered wagons, rope and twine.

US hemp production slowed considerably with the invention of the cotton gin, and came to a halt in 1937, when the Marihuana Tax Act banned the production of all forms of cannabis throughout the United States.

The Farm Bill, passed in 2014, changed the legal status of hemp, and by 2019, 46 states allowed the cultivation of industrial hemp.

Cultivation and processing

Hemp is one of the fastest growing plants on Earth. This amazing annual is tolerant of many soils, and is not bothered by significant pests or disease. Although it may need irrigation, hemp is an environmentally clean crop, as it does not require chemical fertilizers, pesticides or fungicides.

Hemp seed requires warmth (over 70° F) to germinate, but warm climates can count on multiple crops per season. For best fiber production, the seeds are sown thick — between 800,000 and 1,000,000 plants per acre — yielding extra-tall, extra-thin, non-branching stems. In about 80 days, plants can reach up to 12 feet, with an ideal diameter around the thickness of a pencil.

While Cannabis sativa can be also grown for seed — or as a multipurpose crop — hemp grown specifically for fiber is harvested after the plants begin flowering, but well before they start to develop seed. It is usually cut close to the ground, although it can also be pulled manually. After this, processing is similar to flax for linen.

Retting

Hemp fibers are bound together by pectins, which need to be softened and degraded. On a small scale, the stems can be soaked in warm water for about 10 days. On a larger scale, dew retting is preferred. The stems are laid out in the field and exposed to dew, rain and sun, and turned regularly for uniform retting. This process can take four to six weeks, and must be monitored to prevent fiber decay. Retting can also be achieved through the application of enzymes.

Decortication

The outer layer of the hemp stem contains long bast fibers, which must be separated from the woody inner core, or hurd, through a process called decortication. The hurd is broken into small pieces by either mechanical or manual crushing, facilitating extraction of the bast fibers.

Separation is completed through beating, or scutching. Scutching also helps straighten and soften the fibers so they are easier to comb in the next step.

Hackling

Next, the fibers are combed to remove any remaining woody or short fibers and align the bast fibers into a uniform sliver for spinning. To achieve soft, smooth, textile-grade yarn, hackling begins with a coarse comb, and goes through increasingly finer combs to yield a fine sliver for spinning.

Towing

Scutching and hackling remove the shorter fibers (tow) from the bast fibers, but they are not wasted. The tow can be aligned through either manual or mechanical carding and spun into coarse yarns. It can also be used to manufacture products like insulation, fiber board, and mats.

Spinning

Like flax, hemp is often spun wet. Passing the sliver through hot water before spinning softens the remaining pectins, thus binding the fibers so they can be drawn out for a thinner thread. Dry spinning is cheaper, but produces a coarser yarn.

Although hemp’s natural coloring is relatively dark, it takes dyes well and is resistant to fading.

Attributes of hemp

Hemp fabric is a great thermal insulator, and hemp wear will keep you cool in the summer, and warm in the winter. It has antimicrobial properties, and is resistant to both mildew and moths. Because hemp fiber is mostly cellulose, it is also extremely durable, yet still biodegradable. Like linen, hemp fiber has almost no elasticity, so hemp material will neither shrink nor stretch; yet it is less apt to wrinkle than linen.

When you look at the whole plant, its utility is astounding. An estimated 25,000 products can be made from hemp, according to The North American Industrial Hemp Council. Besides clothing, shoes, and accessories from the bast fiber, various paper products, ropes, rugs, and building materials can be made from the short fibers. The hurd makes excellent animal bedding, mulch, wood substitutes and building materials; and the seeds and oil are used in food, supplements and beauty products.

Perhaps the best thing about hemp is its positive impact on the environment. Hemp yields more fiber per acre than other fiber crops, without the use of pesticides, herbicides or fertilizers.

Growing hemp for fiber is basically harvesting carbon, without draining the soil of nutrients required to produce seed. In addition, the nutrient-rich leaves are shed during harvest, acting as a fertilizer for the next crop.

Also enriching the soil is an impressive ratio of root biomass — nearly 20 percent that of the above-ground biomass (which can be two times that of wood crops). The additional organic matter, enhanced microbiomes, and improved soil porosity and drainage that come with increased biomass has proven to increase yields in rotation crops, such as winter wheat.

Hemp is also a hyper accumulator, taking up heavy metals and other contaminants from the soil. It can be used in phytoremediation of contaminated sites, after which the hemp crop can be safely used in solid building materials.

Traditionally valued for its many attributes, then temporarily banned as an illicit drug, hemp is now regarded as a promising, sustainable, multi-purpose fiber crop.